If you’ve ever looked underneath your sink, you’ve probably seen a flexible braided hose, or flexi hose. Particularly in a commercial kitchen, this type of hose solution is often used as it’s tougher and sturdier than other options.

But just because they’re tough, doesn’t mean that they can’t be damaged and burst. And when something bursts in a commercial kitchen, it can cause a huge amount of damage to the property and put your business on hold until it’s fixed. And a flooded kitchen can take a lot of time, money and replacement appliances to get back up and running.

What is a Flexi Hose?

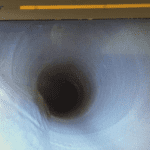

A standard flexi hose is a rubber pipe that’s enclosed in braided stainless steel to protect the rubber. These hoses were created to replace inflexible copper pipes, and are widely used in commercial kitchens and bathrooms across Australia.

They’re an affordable, flexible solution to everything that goes on under a sink. They can easily bend into position and to keep them out of the way in almost any space.

But if you do a Google search, you’ll find a lot of articles on how these pipes can burst, causing damage and end up as a huge expense. Many articles even urge people to rethink their need for flexi hoses. However, there isn’t really an alternative way of connecting a lot of tapware, but there is a different TYPE of Flexi hose.

Why Do Flexi Hoses Burst?

There are a few reasons why these hoses can burst – most of which are preventable and manageable!

If your flexi hose is the standard rubber inner-hose type and has been installed or even packaged incorrectly, weak points can form throughout the hose. If your flexi hose is kinked, stretched too much or twisted, it can weaken the inner rubber hose.

Imagine a kink in a garden hose – where it kinks once, it’s likely to kink in the same place again. That will weaken its integrity of the hose at that point and cause a tear.

The same thing happens in your flexi hose.

Most importantly!

If the stainless steel braiding on the hose is corroded or “rusted”, it weakens the hose at that point as it’s no longer protected. Corrosion means that the inner hose could burst and flood the premises.

Prevent Your Flexi Hose From Causing Damage

Just like any piece of equipment, your flexi hoses have a limited lifespan and need to be regularly checked to ensure that they’re not going to burst. There are three ways that you can ensure your flexi hose isn’t going to cause you damage.

-

Use Quality Products

At Emu Plumbing, we stock only 15 year warranty PEX or Polyamide hoses from Ram or Abey . Because only the best is good enough for your commercial job.

The polyamide hoses offer high-strength, non-metallic, non-rust braiding similar to kevlar material that’s used in bulletproof vests! The manufacturers are so sure of these hoses, that they come with a 15 year warranty. The regular warranty for standard flexi hoses is 5 or 10 years (if they come with a warranty at all!) So you can be sure the ones Emu Plumbing use are the best on the market. -

Correct Installation

A licensed and experienced commercial plumber can carry out all installation work. Even though the job may seem simple, having the right tools, know-how and equipment can make all the difference to preventing a leak or kink. So your flexi hose can last as long as possible. -

Regular Maintenance

A commercial plumber can regularly check and maintain your flexi hose to ensure that it’s not kinked or corroding – that way they can make any replacements necessary before the worst happens!

Flexible braided hoses are required to have a WaterMark certification to ensure your hose reaches the current standard of quality. Your commercial plumber can check that the standards are being met and put together a maintenance schedule to regularly check your flexi hoses.

So you’ll save time and money!