In the world of plumbing and drainage, efficiency is key to preventing major disruption to everyday life. Traditional pipe repair and rectification methods often involve planning, excavation and extended timelines, leaving homeowners and businesses alike facing significant inconveniences.

Thankfully, recent advancements in technology have introduced solutions such as robot cutting and grinding and pipe relining to get you back up and running in no time. This technology allows us to rehabilitate your stormwater and sewer drainage pipes with minimal disruption and impressive speed.

At Emu, we’ve been using robotic and pipe relining tech for years now! And as a result we’ve got real-word examples of how we’ve used this technology to save time and reduce hassle in just hours or days.

Case Study 1: Palm Beach Sewer Robot Grind & Reline

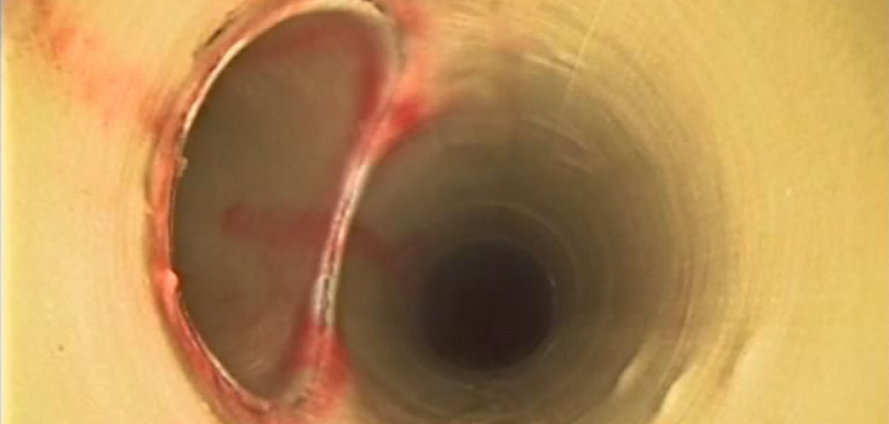

In a challenging Palm Beach project, the sewer system required urgent rectification due to significant concrete ingress. The traditional approach of excavation would have meant prolonged disruptions and an extremely difficult excavation. However, with robotic cutting and pipe relining, we were able to get the job done quickly. Using state-of-the-art robotic technology, the team performed a cut and re-route followed by a reline of the once concrete filled and damaged sewer pipes.

Remarkably, this entire process was completed in just two and a half days, ensuring minimal impact and restoring the sewer system to optimal condition with impressive speed. This allowed the builder to continue working on the project with less hold ups.

Case Study 2: Junction Patch in Coomera

As is typical with plumbing, we attended the Coomera property to complete a routine 1m reline patch, but found it was not as first thought. After inspecting the area with CCTV drain cameras the scope of the project expanded due to extensive damage to a junction. Luckily we also came prepared! We cleaned the pipe using a Picote machine and water jetter, then installed a junction liner to repair the breaks. We were able to complete the entire project there and then, without having to return at a later date!

Case Study 3: Robot Cut & Patch Repair at New Warehouse in Wacol

A new warehouse in Wacol encountered unexpected damage to its drainage system. Following a CCTV inspection of the drainage, it was determined that traditional repair methods were not really an option, as the damage was found to be directly under a newly completed carpark and close to building posts. Our solution was a robot-assisted cut and reline patch repair. By using cutting-edge technology, the team completed this challenging job in under two days and without damage or a need to excavate any of the new carpark.

These are just a few examples of the hundreds of relining jobs we’ve completed across Brisbane – and there’s always more! With drainage often hidden underground or in hard to access areas, we’re constantly finding damage and challenges we’re not expecting. Whatever the challenge, our professional pipe relining team along with high tech equipment are keen to attack it!